Better machinery use can change the game in manufacturing. Did you know a top injection molding maker increased its efficiency by 7% in three months? This led to a $1.2 million profit boost across six plants.

Today, being efficient in manufacturing is key to growing. This piece will show you how great machinery can lift your company to new, big levels. By using the latest technologies and smart moves, you can handle problems, use resources well, and lead.

This guide is here to give you power as a maker. It will help you choose smart moves to boost your machinery and equipment’s efficiency. This will mean more money and better chances against the competition. Get ready to see how far your production lines, manufacturing systems, and industrial robots can go with CNC machines and mechanical engineering.

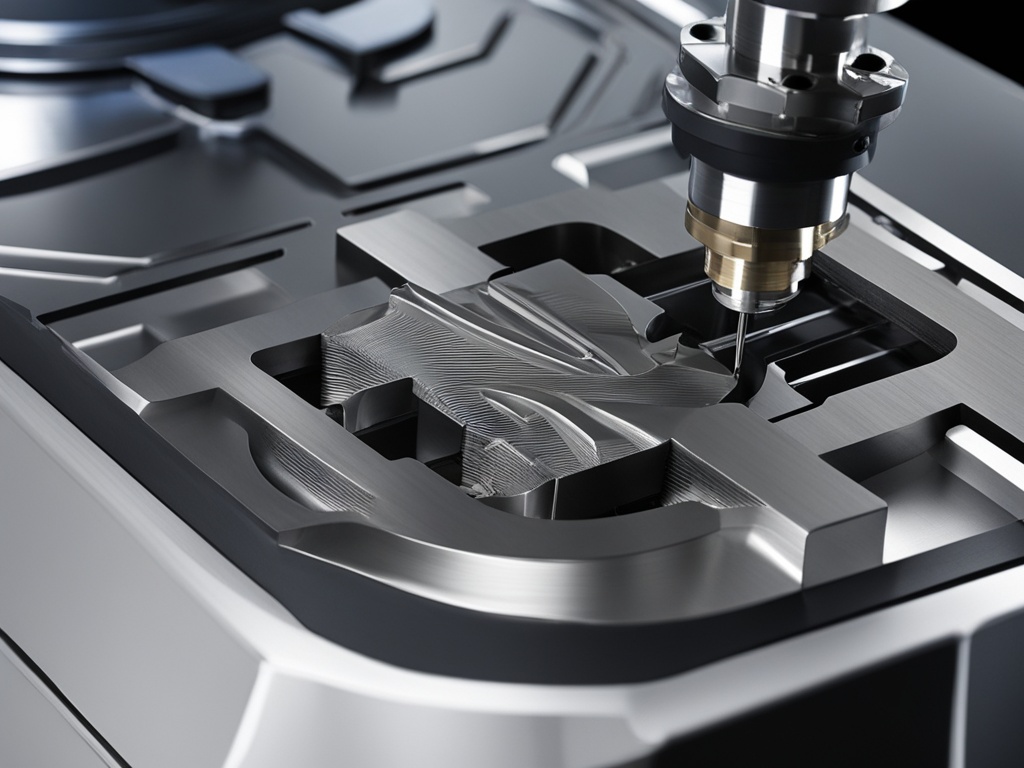

Unveiling the Power of CNC Machining

In today’s manufacturing world, CNC machining is a real game-changer. It uses computer control to make precisely designed parts. This high-tech process sets new standards for accuracy and precision manufacturing.

Precision and Consistency Redefined

CNC machining can move on five axes, which is unique. It can create very detailed parts in one go. This saves time and ensures every piece is exactly the same. It’s perfect for jobs that must be nearly perfect.

Automated Production for Streamlined Workflows

CNC has changed how we make things by automating tasks. This makes the process faster and uses resources better. It helps meet customer needs quickly and at lower costs.

Flexibility and Versatility: Machining Mastery

The real power of CNC machining is how well it can work with different materials. It handles everything from hard metals to soft plastics. This adaptability makes the process quick and efficient, keeping businesses competitive.

No matter the industry, CNC machining can boost your abilities. It raises your precision levels and helps your business grow in productivity and profit.

Strategies for Maximizing machinery Efficiency

To make your machinery work better, use many strategies together. This way, you can really boost how well your machines work. Making your manufacturing efficient is key.

Lean Production: Eliminating Waste, Optimizing Processes

To better your operations, start with lean principles. They cut out waste and make things flow smoother, boosting productivity. Look into where you can cut waste, such as too much inventory or extra work steps.

Skilled Workforce: The Key to Precision and Productivity

Having skilled workers is essential for efficient machines. They need to know the ins and outs of the equipment to keep it running smoothly. Training and updating their skills is a must.

Optimizing Cycle Times and Maintaining Realistic Expectations

Keep your production goals real and achievable. See where you can make things move faster without lowering quality. This approach helps meet your goals while avoiding too much pressure on your team.

Unleashing the Full Potential of CNC Machines

Unlocking your CNC machines’ full potential boosts efficiency. It involves using high-performance machining, smart coolant management to cut costs, and buying top-notch cutting-edge tools and accessories.

Pushing the Limits: High-Performance Machining

New CNC machine and cutting tools let makers improve productivity and cut waste. For example, Cincom Citizen’s LFV technology reduces tool vibrations, making cuts smoother and surfaces better. This tech boosts tool life, lets you cut faster without losing quality, and speeds things up.

Efficient Coolant Management: Minimizing Costs

Managing coolant well boosts your CNC operations’ efficiency. LFV’s adaptive control is great for long production runs. Better coolant means tools last longer, less downtime, and fewer wastes, saving money and helping the planet.

Cutting-Edge Tools: Investing in Quality

Good high-performance machining tools are essential for CNC success. Cincom Citizen’s LFV tech is good for all kinds of materials. Choosing quality increases productivity, cuts waste, and ensures great results every time.

Continuous Improvement: The Pathway to Efficiency

Getting the most out of machinery is a constant goal. It’s all about always looking to improve. Manufacturers look closely at how things are made to find any issues. Then they work to make operations smoother and work better. This process covers how to check and make work better, get rid of stops, and use better ways to make things happen smoothly.

Analyzing and Optimizing Workflows

Studying and making work better is key to getting machinery right. Looking closely at each part of making something lets you find places to get better. This is about cutting out anything that’s not needed and making everything work better. Lean manufacturing and Kaizen can really help here. They get everyone focused on always improving and teaching them how to fix problems.

Eliminating Unnecessary Pauses and Delays

Another important step is getting rid of stops and slow times. If you watch how things are made and where they slow down, you can do better. You can find ways to speed things up and make them run smoother. This might mean using new tools, organizing things better, or teaching workers new skills.

Implementing Advanced Strategies: Constant Surface Speed and More

Taking things further, you might want to try out new ways to make things work better. Like with CSS machining, the tools move at a steady speed. This makes them last longer, speeds things up, and makes things look better. Always looking to do better and using new ideas in making things can make a big difference. It can help you do more and be the best in your field.

Conclusion

Getting the most out of your machinery is key in the world of manufacturing today. It’s all about using the best CNC technology, the right strategies, and always trying to do better. With this approach, companies can improve their work a lot, use their resources better, and keep ahead of others.

Embedded in this text are tips and plans that can really help manufacturers. It’s all about making smart choices, boosting how your industrial equipment works, and setting up for success in the long run. By focusing on being more effective, companies can save money, make their products better, and meet what their customers want, leading to more chance of success.

Always working towards working better is something that never stops. But with the ideas and methods in this today’s chat, you can take your work to a higher level, leading the way in competition, and reaching big success like never before.